What Is A Torque Bolt Chart?

Torque helps create tension while bolts are used to fasten two components together to enable them to resist tensile and shearing forces. A...

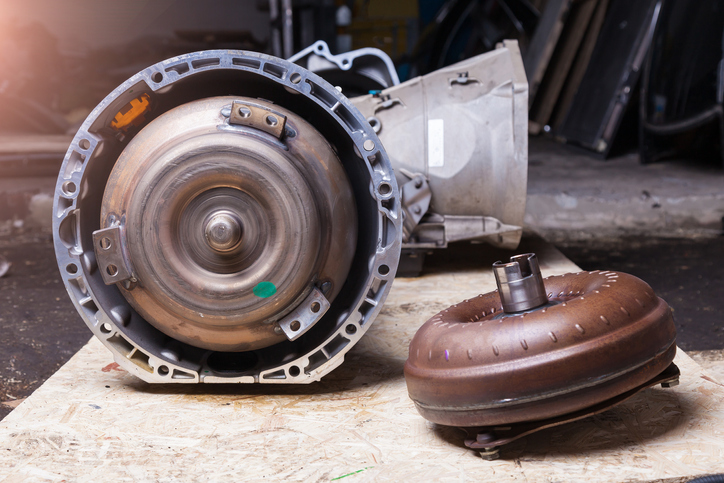

A torque converter is a must-have for an automatic transmission vehicle. And installation is not complete without the proper use of torque converter bolts.

These bolts are designed to hold your torque converter and the flexplate in place. A poor installation results in strange knocking noises coming from the bolts and revolving around the load.

Why are these bolts important? And how do you know if your bolts are loose? Let’s take a closer look to find the answer to each of these questions.

The torque converter acts as a link between the power source and the load. The flexplate connects its input to the engine crankshaft. The flexplate turns when the engine runs. As a result, the torque converter also turns, making the hydraulic pump power up.

Here is a quick guide on installing torque converter bolts.

The recommended torque for this type of bolt is 45 ft/ lb. Incorrect installation of the bolts would lead to improper seating of the torque converter, resulting in fluid pump failure.

Most of the time, people confuse a faulty torque converter with problems resulting from the transmission. Due to this, you might spend your resources working on the transmission, while the problem might be the torque converter. Signs to look out for a loose bolt include:

High Levels Of Slippage

When the bolts are loose, the torque converter fails to function properly. It will fail to properly regulate fluid, making it take more or less than is required. This leads to low acceleration due to slipping gears.

Depending on the manufacturer's guidelines, the bolts are supposed to be torqued in a crisscross pattern. A knocking sound in a moving vehicle may be a problem. Loose torque converter bolts will accelerate the sound when the transmission gears are interconnected. The rattling sound can also result from a crack between the bolt holes.

Gear Shift

A loose bolt lowers the vehicle's pressure output. For this reason, the gear shift tends to feel soft or delayed. This can be solved by raising the engine RPM to increase the output pressure of the torque converter.

Inconsistent Vehicle Speed

If your bolts are loose, you may experience sudden and inconsistent vehicle speed changes. When this happens, the fluid pressure becomes unsteady, making the throttle break down. Inconsistent speeds may also affect the fuel efficiency of your vehicle, so it’s important to get it checked out.

Shuddering

A shuddering vehicle might be due to problems with the torque converter. The vehicle appears to be vibrating even when not being driven at a higher speed. The feeling is very noticeable, sudden, and usually not consistent.

Getting the right fastener is the first step to guaranteeing success in your next project. Quality bolts are not hard to find when you're working with a company like Big Bolt. We take pride in supplying a wide variety of fasteners for your needs. Additionally, if we don't have one, we'll manufacture it immediately for you with a quick turnaround time of up to 24 hours.

Contact us today to get a quote for your next project.

Torque helps create tension while bolts are used to fasten two components together to enable them to resist tensile and shearing forces. A...

No one wants to talk about bolt failures. Bud despite being the smallest element of a structure, bolts play a critical role in ensuring...

Bolt head markings are a combination of letters, numbers, or both to help you identify the fastener that you’re looking for. If you know...